About Us

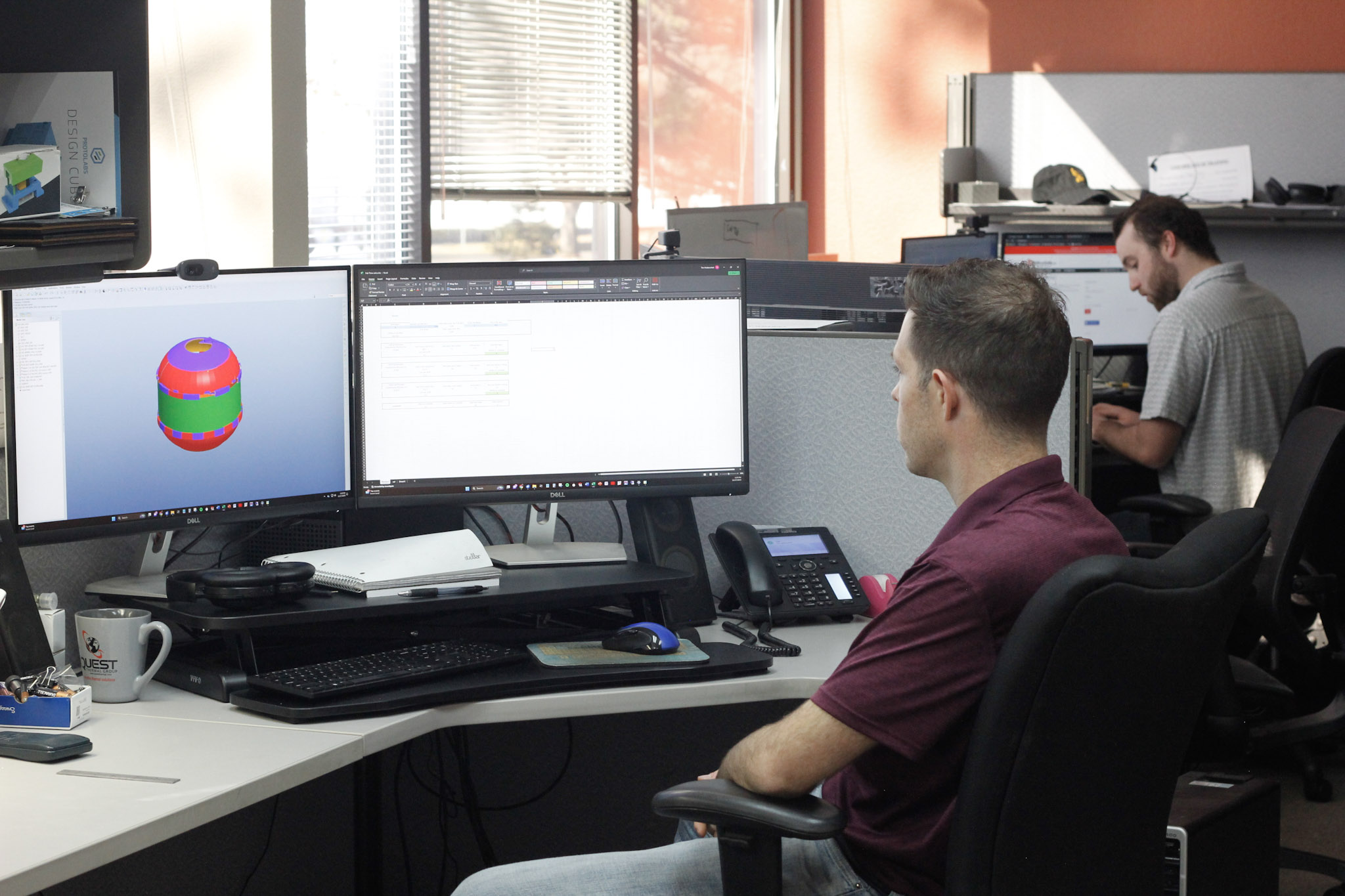

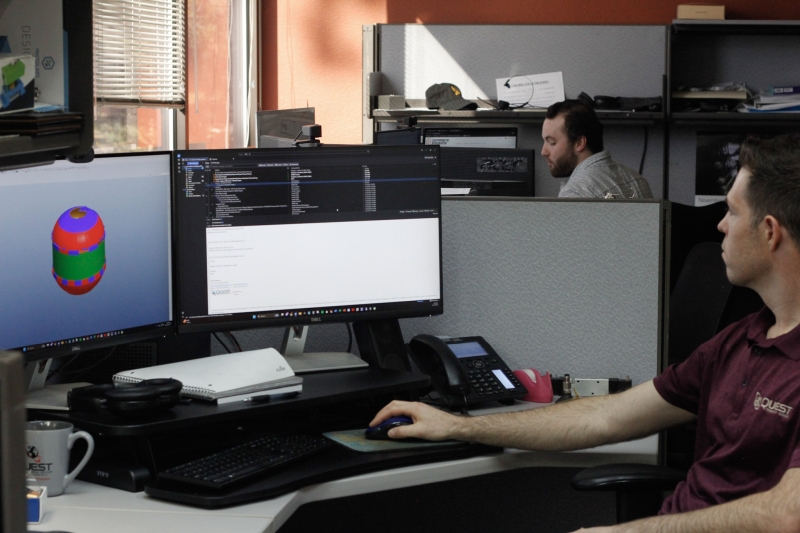

Quest Thermal Group is a technology development engineering firm, specializing in the design and manufacture of advanced thermal insulation systems, offering the highest performance available. Our team of engineers and scientists has been developing advanced thermal systems since 2006, using proprietary Discrete Spacer Technology™ with low heat flux and unique structural capabilities. We work closely with our customers to provide tailored solutions over the full project lifecycle.

High performance aerospace insulation systems are available for spacecraft, cryogenic propellant vehicles, for in-space, in-air, lunar surface, deep space or Mars ISRU. Commercial superinsulation systems are in development for hydrogen fueled aircraft, vehicles and infrastructure, as well as cold supply chain, quantum computing, superconducting and commercial/industrial applications. Quest creates next-generation thermal products with substantial benefits over prior state-of-the-art solutions.

Quest manufactures its aerospace insulation products in Class 100,000 (ISO Class 8) environmentally-controlled cleanrooms outfitted with custom manufacturing equipment. Our new robotic automated fabrication line uses the latest in automation and robotic fabrication for significantly increased throughput.

We work with the top names in aerospace and high-technology industries, and possess the tools and expertise to take your concept from note pad to launch pad!