Home

Slide

WE ARE THE

WORLD LEADER

IN ADVANCED THERMAL INSULATION SYSTEMS

At Quest Thermal Group, we drive more innovation in the thermal insulation systems space

than anyone else. High performance, highly innovative.

than anyone else. High performance, highly innovative.

An Overview

Who We Are

At Quest

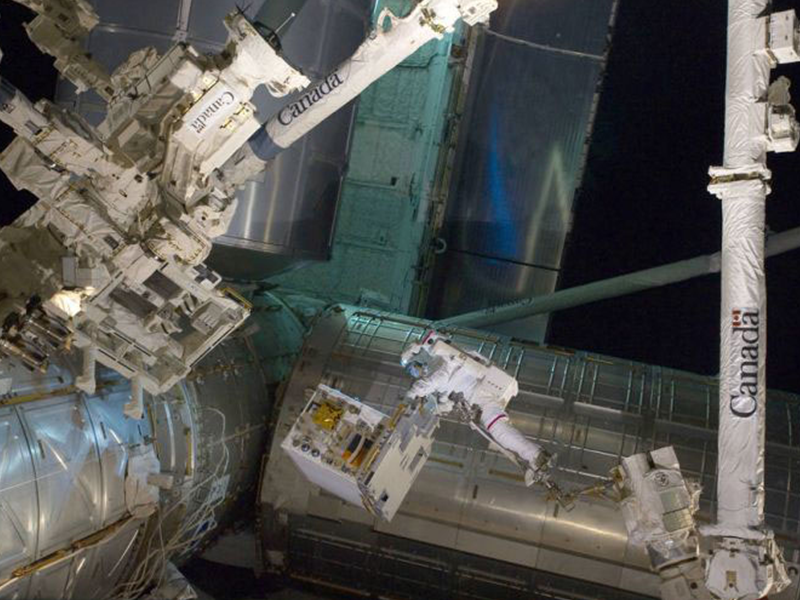

Quest Thermal has successfully developed new technology for NASA and Aerospace Primes since 2006, developing and supplying beyond cutting-edge insulation systems.

Quest Thermal works with you to develop optimal solutions for insulating spacecraft, cryogenic propellant storage and transfer, vapor cooling, load bearing insulation, lightweight vacuum shell insulation, cryofeed line insulation, lunar and Mars ISRU, LH2 storage, cold supply chain and other thermal applications. Quest provides expertise, novel technology and the highest performance thermal solutions for our clients.

What We Build

Our Products

& Technologies

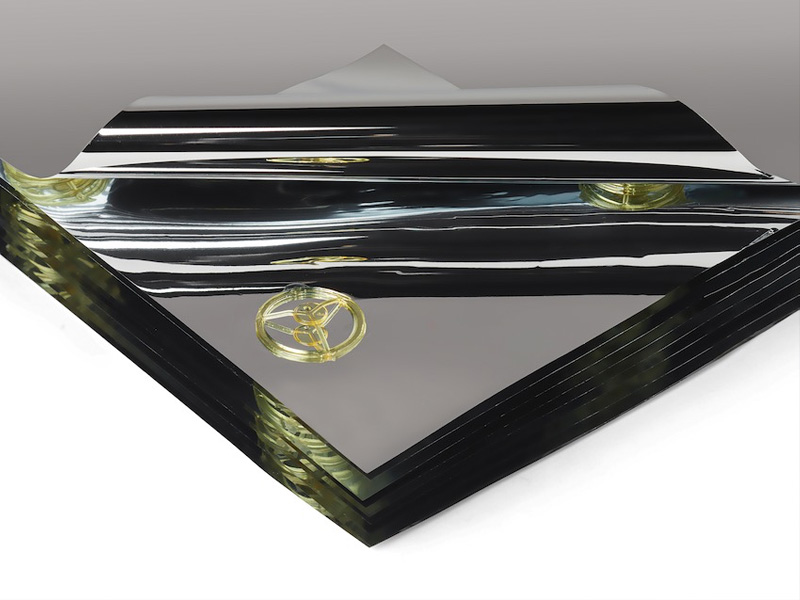

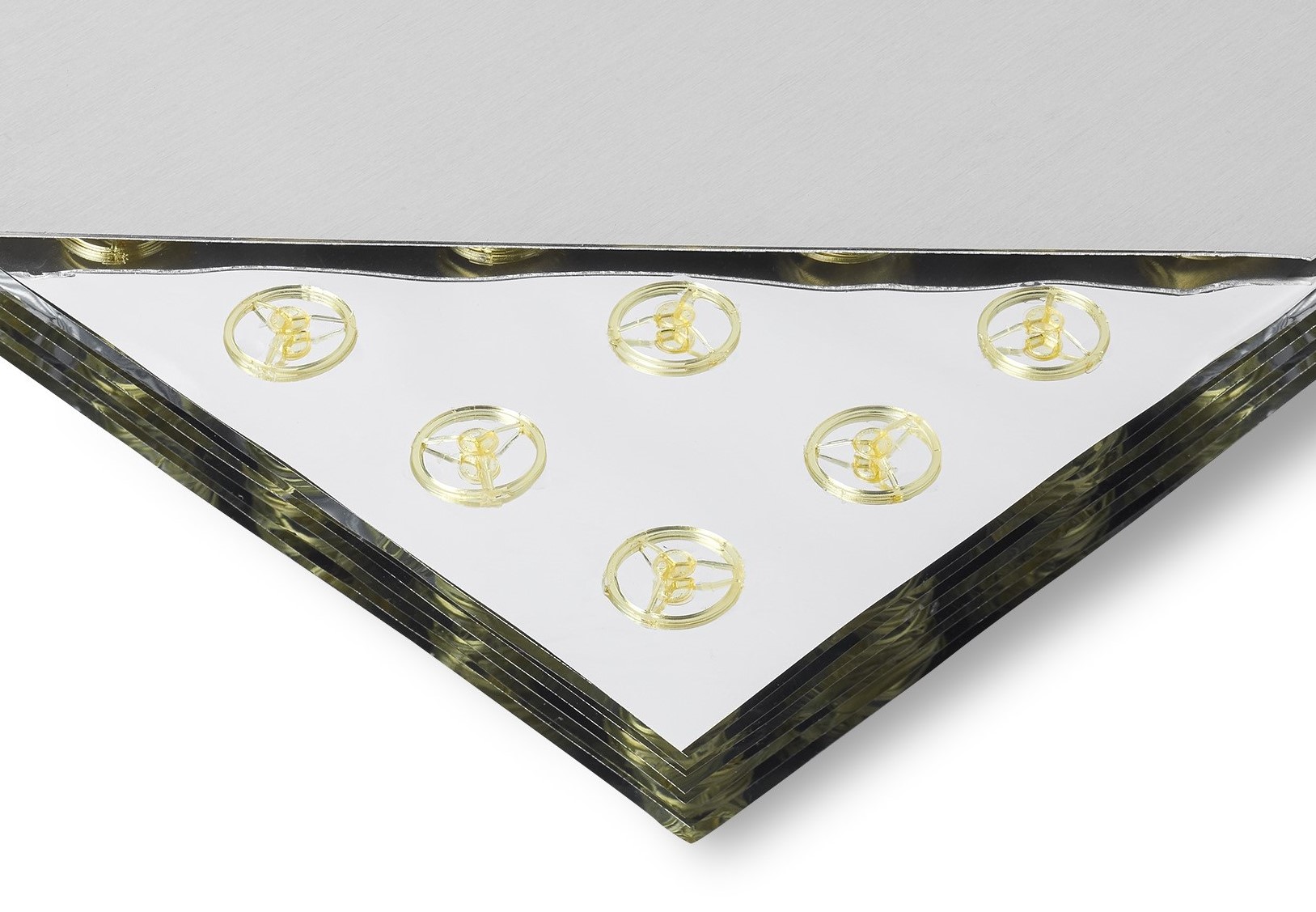

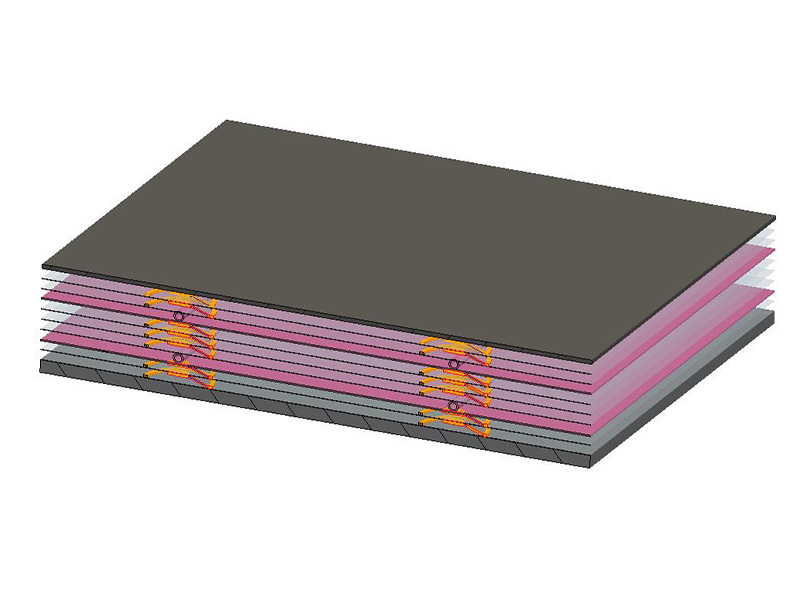

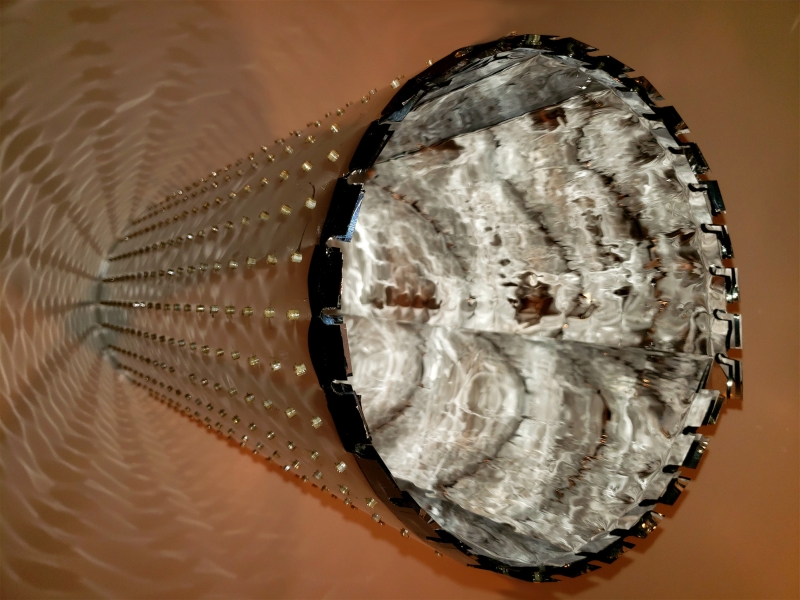

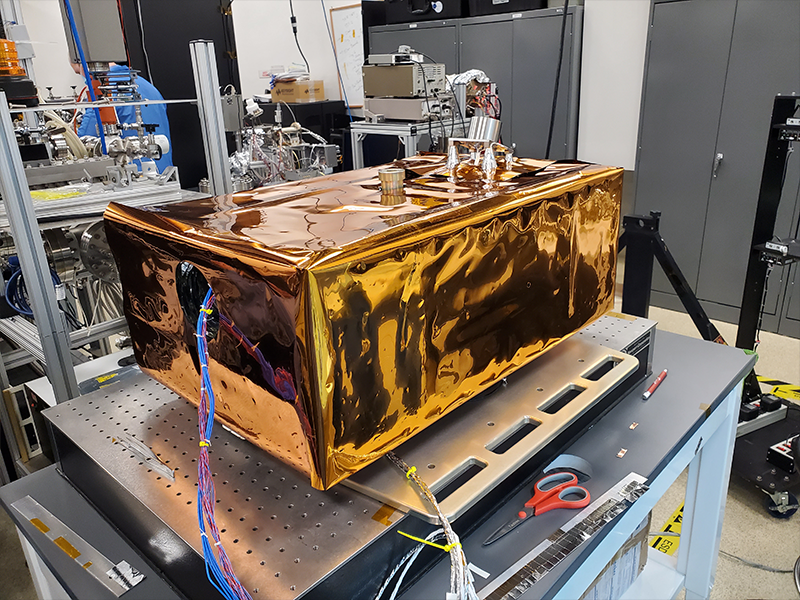

IMLI

Integrated Multilayer Insulation

IMLI is a high performance insulation developed by Quest Thermal Group for NASA. IMLI uses proprietary Discrete Spacer Technology™ with low thermal conductivity polymer spacers to reduce heat leak, control layer spacing and density, and provide unique structural capabilities.

IMLI offers half the heat leak per layer as netting MLI, robust structure, predictable performance, fewer layers and lower mass then netting MLI, can span large spaces and support external loads.

IMLI offers half the heat leak per layer as netting MLI, robust structure, predictable performance, fewer layers and lower mass then netting MLI, can span large spaces and support external loads.

WMLI

Wrapped MLI uses a unique Discrete Spacer designed for cryogenic transfer applications. WMLI offers a 12-fold improvement in heat leak compared to spiral-wrapped netting MLI. Triple Orthogonal Disc (TOD) spacers provide high performance insulation on tube diameters from ¼” up to 6″. WMLI can use 3D printed Nested Shells to accommodate bends, tees, valves, and other plumbing equipment.

LRMLI

Load Responsive/Load Bearing MLI

Load Responsive/Load Bearing MLI is a structural insulation that can carry compressive loads up to 90 psi. A Discrete Spacer dynamically compresses with load - LRMLI supports vapor cooled shields, thin lightweight vacuum shells and other external loads. The spacer’s dynamic response to external load provides optimal performance both in-air and in-space, and LRMLI/LBMLI can be designed for a specific load and mission requirement.

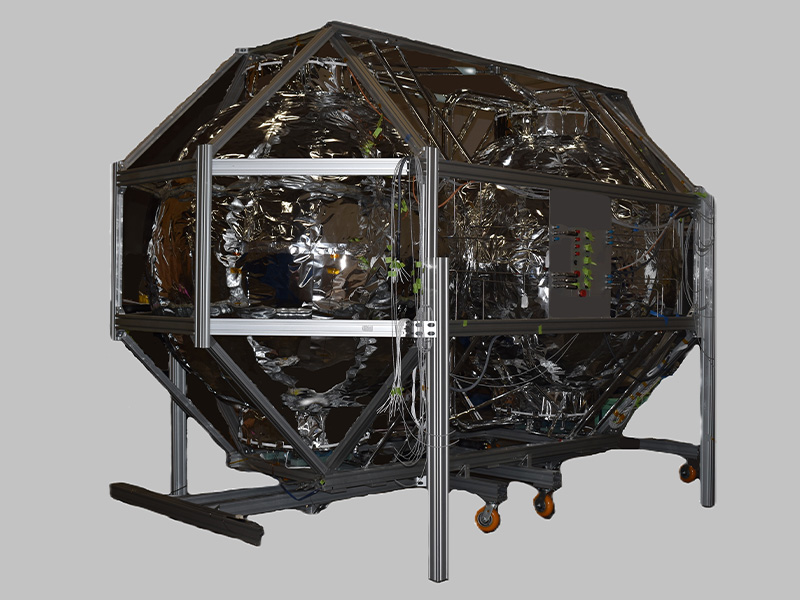

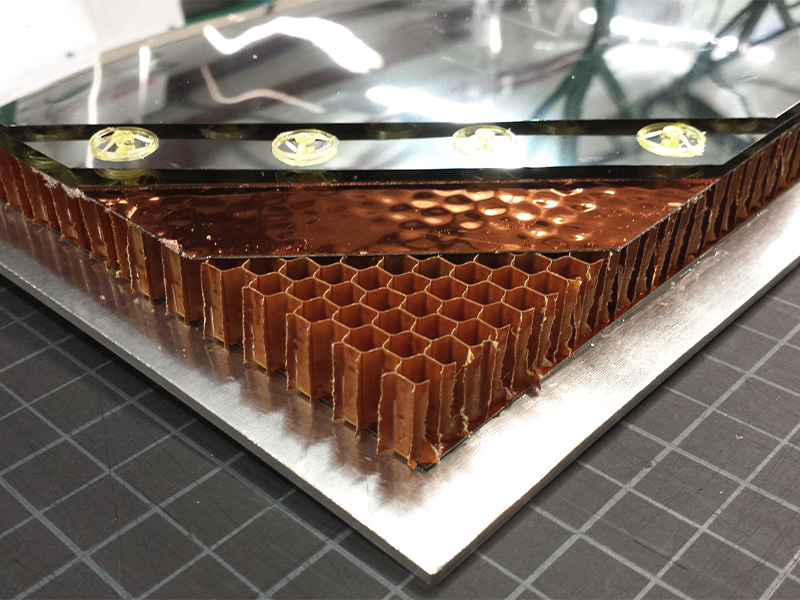

Vac Shells

Lightweight Vacuum Shell

Insulation Systems

Insulation Systems

Discrete Spacers provide structural support, allowing thin, lightweight vacuum shell insulation. Self-supported and spacer-supported metal or composite vacuum shells for various external pressures have been designed. These systems are ideal for LH₂ storage for aircraft and vehicles, launch vehicles and Mars surface ISRU.

Vapor Cooling

Advanced Vapor Cooled Technology

Quest Thermal has worked on more than 10 R&D programs for NASA and Aerospace Primes developing new vapor cooling methods and insulation systems. IMLI supports embedded Broad Area Cooled shields with our low heat leak discrete spacers, and can provide optimal passive or active vapor cooling. A number of new Quest technologies provide novel, highly efficient vapor cooling methods with low mass.

Integrated vapor cooling within IMLI routinely provides 50% to 70% reduction in heat flux using passive LH₂ boiloff, and helps achieve Zero Boil Off with actively cryocooled systems.

Integrated vapor cooling within IMLI routinely provides 50% to 70% reduction in heat flux using passive LH₂ boiloff, and helps achieve Zero Boil Off with actively cryocooled systems.

Superinsulation

Commercial Superinsulation

Quest Thermal has developed a lower cost discrete spacer insulation for commercial superinsulation applications. Our commercial insulation offers high thermal performance for industrial and residential uses including refrigerators, freezers, cold supply chain, LNG and LH₂ transport. A 5mm thick system offers R-values > 100, significantly better thermal performance than R-7 foam.

Other Techs

Other Quest Technologies

Launch Vehicle MLI

MMOD Insulation Systems

Lightweight LHe Dewars

Highly Variable Spacecraft Radiators

Deployable Sunshields

MMOD Insulation Systems

Lightweight LHe Dewars

Highly Variable Spacecraft Radiators

Deployable Sunshields

High Temperature MLI

Commercial Superinsulation

LH₂ Storage Systems

Superconducting Applications

Commercial Superinsulation

LH₂ Storage Systems

Superconducting Applications

The Latest

NASA Selects First Lunar Instruments for Artemis Astronaut Deployment

NASA Selects First Lunar Instruments for Artemis Astronaut Deployment

March 27, 2024

NASA has chosen the first science instruments designed for astronauts to deploy on the surface of the Moon during Artemis III. Once installed near the lunar South Pole, the three instruments will collect valuable scientific data about the lunar environment, the lunar interior, and how to sustain a long-duration human presence on the Moon.

New Robotic Automation Initiative Will Elevate Manufacturing Capacity and Precision

New Robotic Automation Initiative Will Elevate Manufacturing Capacity and Precision

February 9, 2024

Quest Thermal Group, a world-leader in innovative thermal management solutions, announces the initiation of a robotic automated fabrication effort aimed at revolutionizing its manufacturing processes. This strategic move reflects Quest's commitment to advancing technology, enhancing precision, and ensuring the highest quality standards while meeting the growing manufacturing needs their clients.

Quest Thermal Group Successfully Passes Rigorous Quality Audit Conducted by Blue Origin

Quest Thermal Group Successfully Passes Rigorous Quality Audit Conducted by Blue Origin

January 12, 2024

Quest Thermal Group, a leading provider of cutting-edge thermal management solutions, proudly announces the successful completion of a comprehensive quality audit conducted by Blue Origin, a private aerospace manufacturer and spaceflight services company. This achievement highlights Quest Thermal Group's commitment to excellence and its capability to meet the stringent standards set by industry leaders in the space exploration sector.

Humanity’s Return to the Moon: Quest Joins Forces with Lockheed Martin on Lunar Exploration Transfer Vehicles

Humanity’s Return to the Moon: Quest Joins Forces with Lockheed Martin on Lunar Exploration Transfer Vehicles

January 10, 2024

Quest Thermal, a leading innovator in thermal management solutions, is thrilled to announce a groundbreaking collaboration with Lockheed Martin, a global aerospace and defense company, to pioneer advancements in lunar transfer vehicles. This strategic partnership aims to accelerate the development of state-of-the-art technologies crucial for the future of lunar exploration.

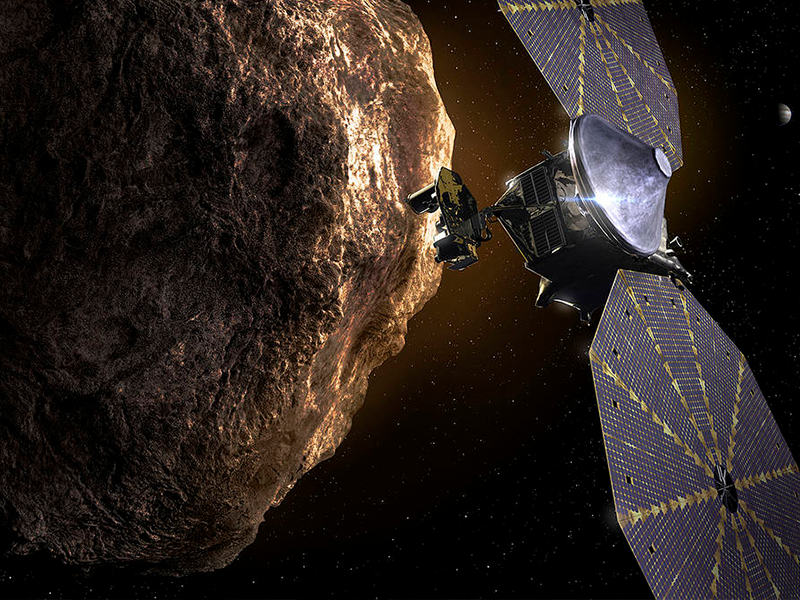

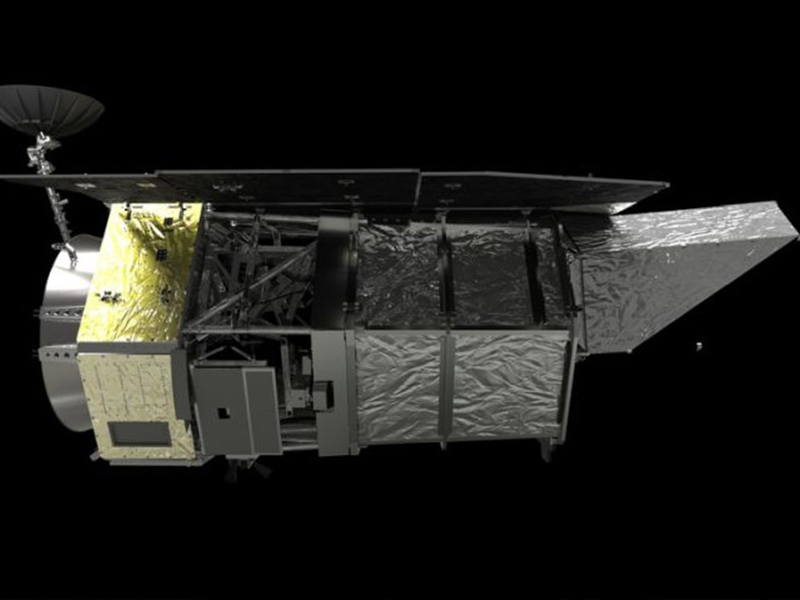

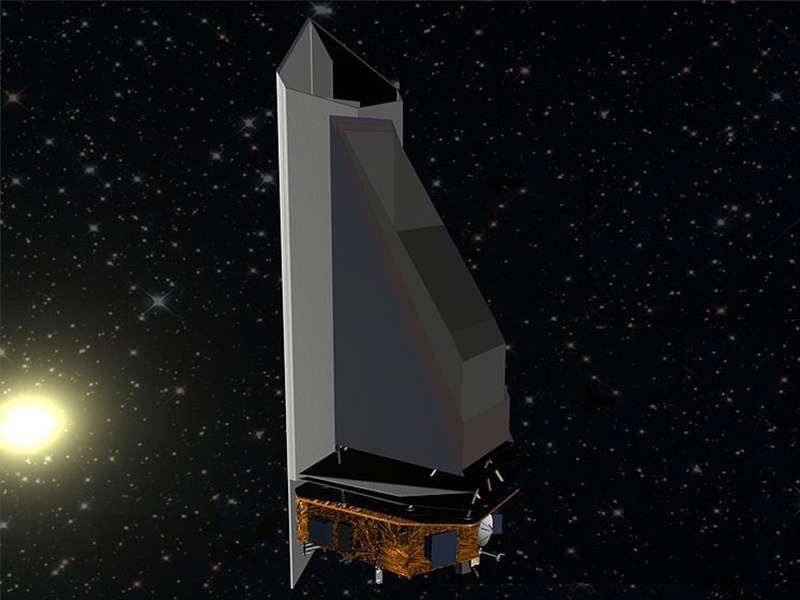

IMLI To Insulate NASA Near Earth Object Surveyor (NEOS) Space Telescope

IMLI To Insulate NASA Near Earth Object Surveyor (NEOS) Space Telescope

December 15, 2023

Quest Thermal's cutting-edge Integrated MultiLayer Insulation (IMLI) has been chosen by Ball Aerospace and NASA to insulate the NASA NEOS infrared space telescope. The Near-Earth Object Surveyor space telescope is designed to help advance NASA’s planetary defense efforts to discover and characterize most of the potentially hazardous asteroids and comets that come within 30 million miles of Earth’s orbit. By detecting and characterizing these celestial bodies, NEOS contributes to planetary defense and scientific research.

Quest Thermal Group Invited to Blue Origin Supplier Summit

Quest Thermal Group Invited to Blue Origin Supplier Summit

December 12, 2023

Quest Thermal Group, a trailblazer in the field of thermal management solutions, is honored to announce its participation in the Blue Origin Supplier Summit. This invitation serves as a recognition of Quest Thermal Group's dedication to excellence, innovation, and its pivotal role in advancing technologies crucial to the aerospace industry.

Humanity’s Return to the Moon: Quest Joins Forces with Lockheed Martin on Self-Deploying Sunshield Technology

Humanity’s Return to the Moon: Quest Joins Forces with Lockheed Martin on Self-Deploying Sunshield Technology

October 10, 2023

Quest Thermal Group, a renowned leader in thermal management solutions, proudly announces its collaboration with Lockheed Martin on a groundbreaking Cryogenic Demonstration Mission. This joint venture brings together Quest Thermal Group's expertise in cutting-edge thermal technologies and Lockheed Martin's prowess in aerospace innovation to advance cryogenic systems for future space exploration.

Quest Showcases New MLI Electrical Grounding Technology & Vapor Cooling Methods at Space Cryogenics Workshop

Quest Showcases New MLI Electrical Grounding Technology & Vapor Cooling Methods at Space Cryogenics Workshop

July 16, 2023

Quest Thermal Group attended the 2023 iteration of the prestigious Space Cryogenics Workshop held in Kona, Hawaii. The company presented two technical papers highlighting advancements in cryogenic thermal technologies. This engagement underscores Quest's continued commitment to pushing the boundaries of innovation and sharing expertise with the global space exploration community.

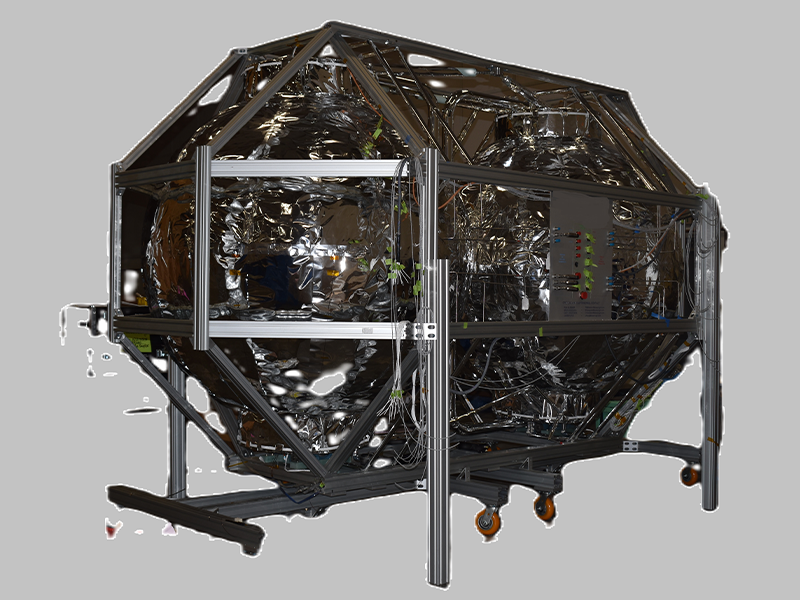

IMLI Chosen For NASA Cryocooler Test Program To Achieve LH₂ Zero Boil-Off

IMLI Chosen For NASA Cryocooler Test Program To Achieve LH₂ Zero Boil-Off

May 9, 2023

Quest Thermal Group, the world-leader in advanced thermal insulation systems, proudly announces its collaboration with NASA on the groundbreaking LH₂ Two Stage Cryocooled Zero Boil Off test program. This partnership reflects Quest Thermal Group's commitment to advancing cryogenic thermal technologies and contributing to NASA's ambitious goals for space exploration.