Wrapped (WMLI)

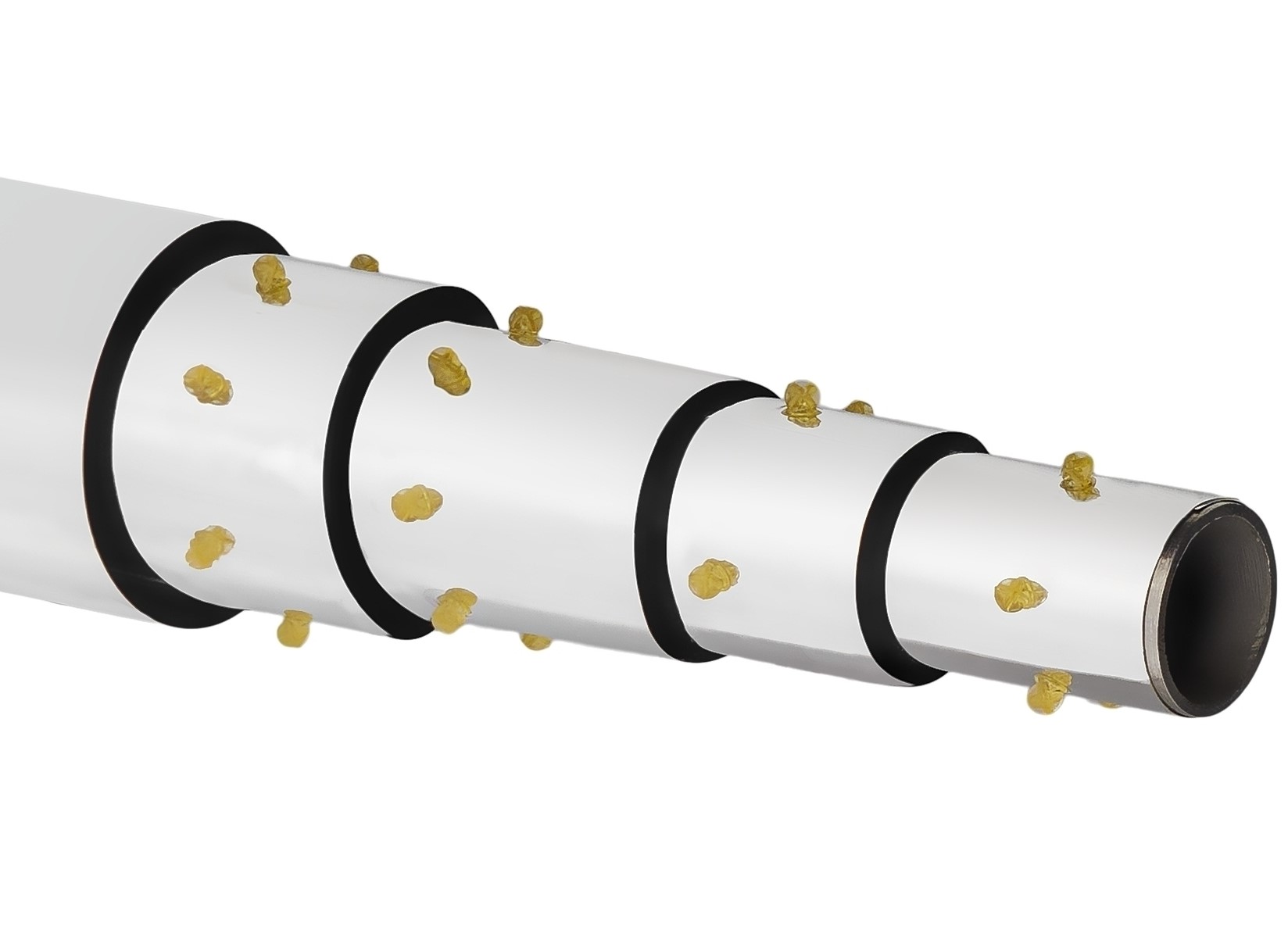

Wrapped MLI (WMLI) is a game-changing thermal solution that revolutionizes cryogenic feedline insulation. WMLI’s innovative design utilizes discrete spacer technology and nested low emissivity shells. These unique features are specifically engineered to reduce heat flux in cryogenic piping, making it ideal for applications where minimizing heat transfer is critical.

Compared to conventional netting MLI, WMLI offers remarkable performance with 12-fold lower heat flux on cryogenic pipes. WMLI’s patented polymer spacers—formed from Triple Orthogonal Disks—maintain precise layer spacing. This design minimizes interlayer contact and solid heat conduction, resulting in exceptional insulation performance.

WMLI is an engineered solution for your application, heat flux requirements and geometries. By working with our team, we provide engineering design, system analysis, and the fabrication and installation of our highly-modular WMLI systems.”

Applications

AEROSPACE

- Cryopropellant transfer lines

- Actively cryocooled coolant lines

- In-space propellant transfer

- Lunar and Mars ISRU coolant and transfer lines

- Launch facilities & GSE

COMMERCIAL

- Vacuum jacketed piping

- LH2 aircraft fuel systems

- LH2 applications and infrastructure

- Superconductor cooling

- Industrial hot/cold transfer piping

Contact us today to discover how WMLI can reduce heat leak to your feedlines.